Services

Home > Services

Home > Services

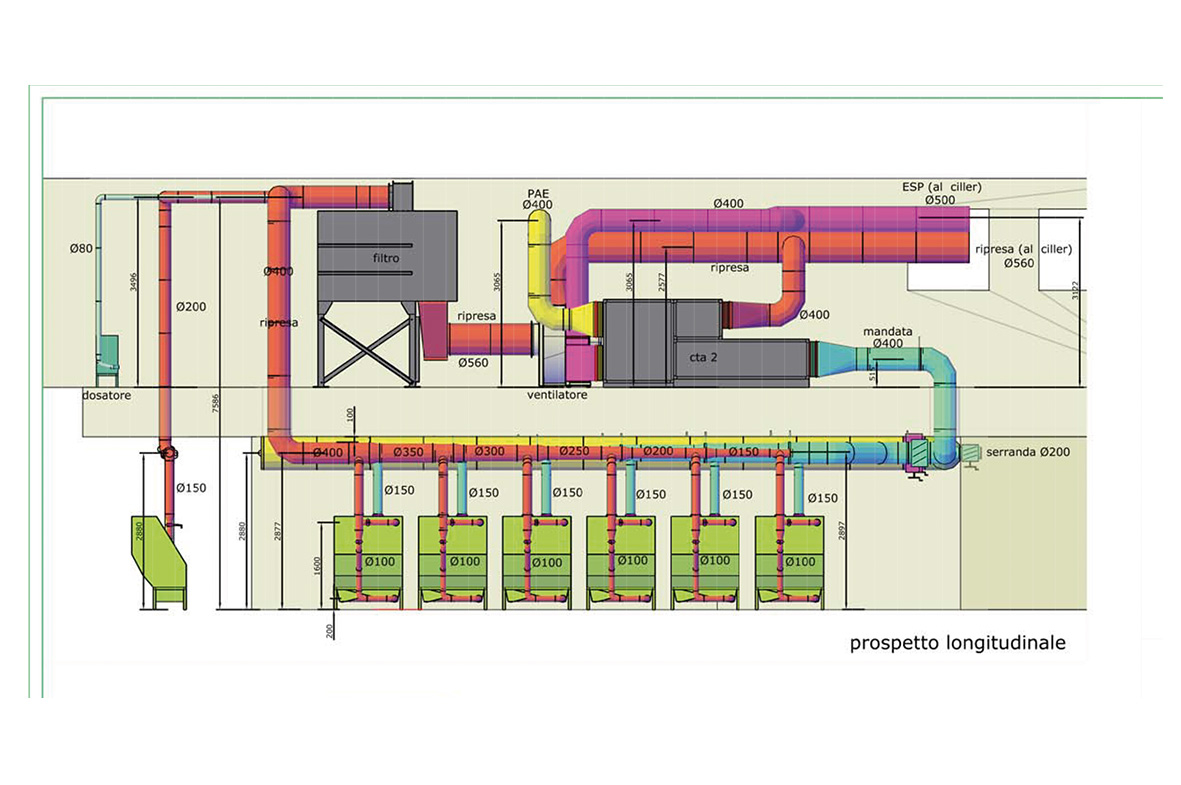

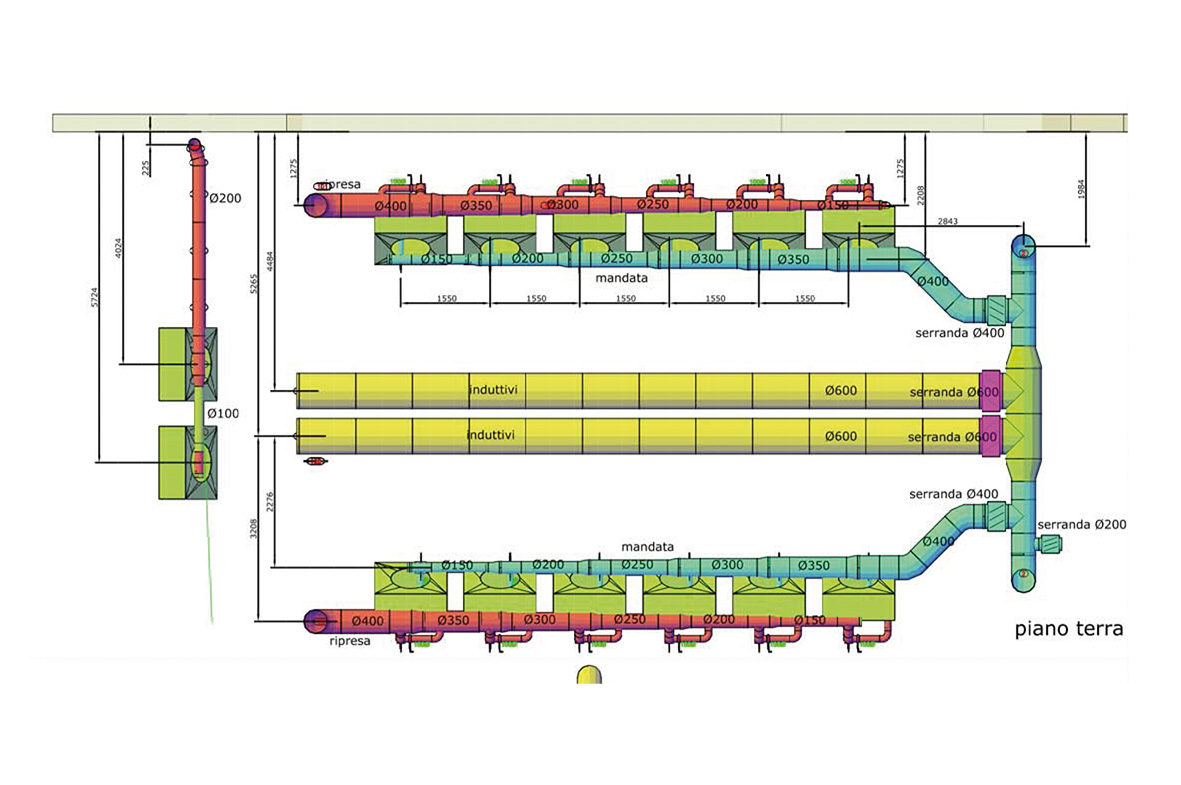

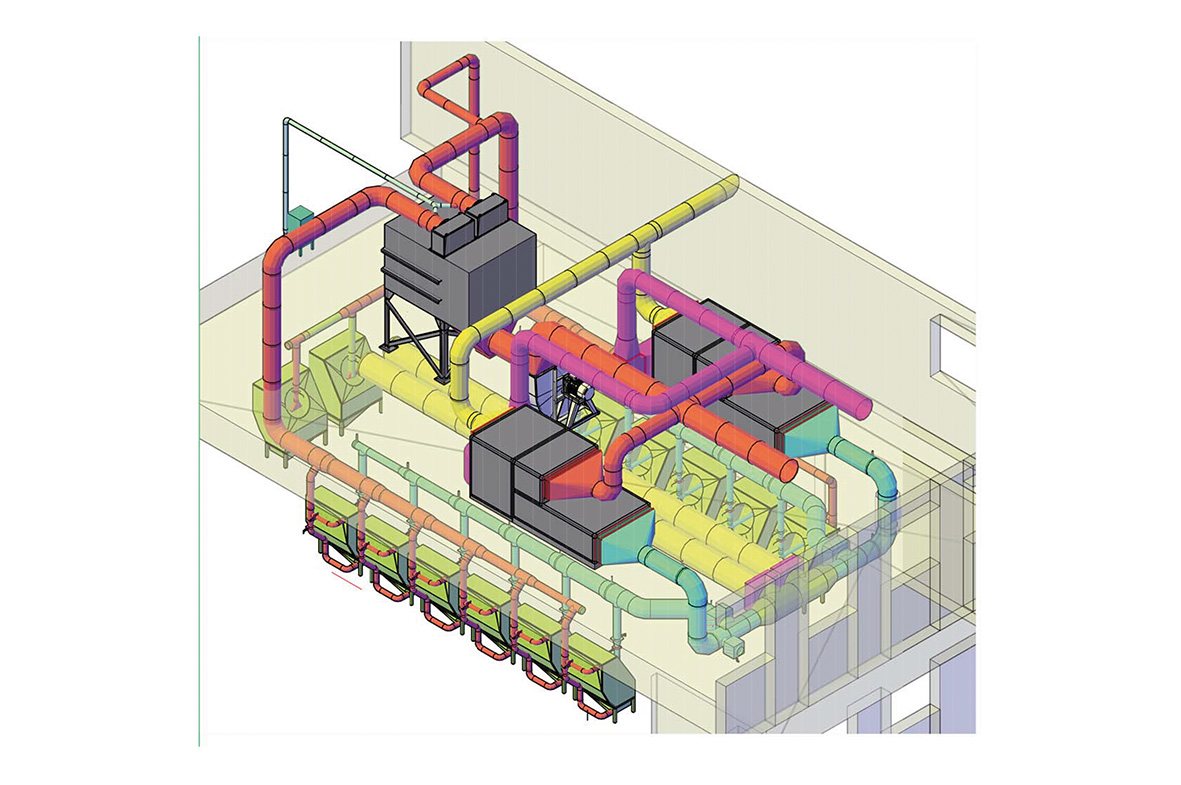

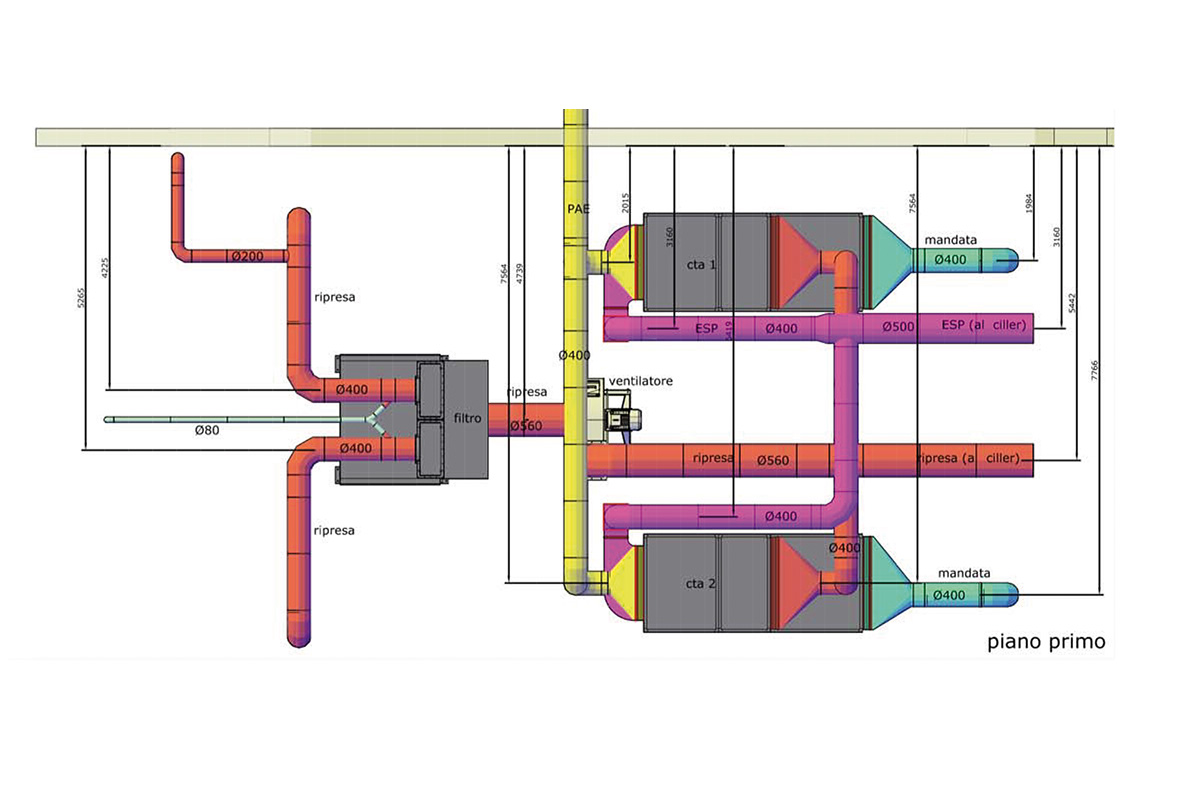

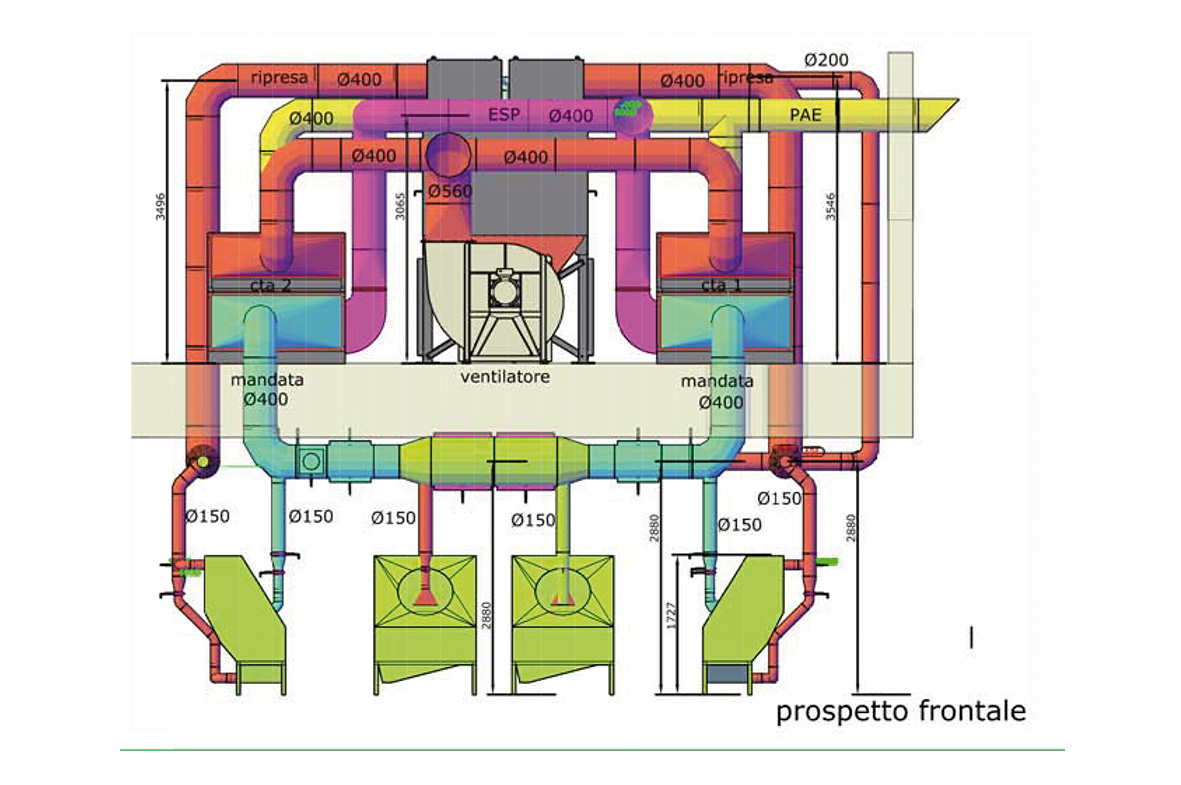

IRTERM’s own technical team carry out the technical and construction planning of the HVAC system.

AIRTERM’s remarkable design expertise, developed over 30 years, means we can tackle and meet any air conditioning, heating, and ventilation needs, in all industrial, pharmaceutical, hospital, commercial, executive, airport, and infrastructure environments.

From the site survey to the system interference analysis, from the graphical rendering of the various designs using cutting-edge computer tools, to the construction details to the as-built final product.

It is very important to calibrate aeraulic systems to ensure the system works properly in terms of performance and energy efficiency.

Specifically, for extensive multi-zone systems, calibration and balancing require knowledge of the main phenomena related to the operation of aeraulic systems and the specific procedures for instrumental inspections.

AIRTERM uses its own sealing gauges to perform tests on aeraulic systems in accordance with technical standards:

AIRTERM has the skills to plan and carry out scheduled maintenance activities for the aeraulic systems it performs and installs.

Taking care of periodic, ordinary or extraordinary, preventive and predictive maintenance means being unique interlocutors with technical and organizational skills, typical of a consolidated and expert structure, to avoid accidents and breakdowns, keep the system in compliance with the various regulations and guarantee better operating performance.